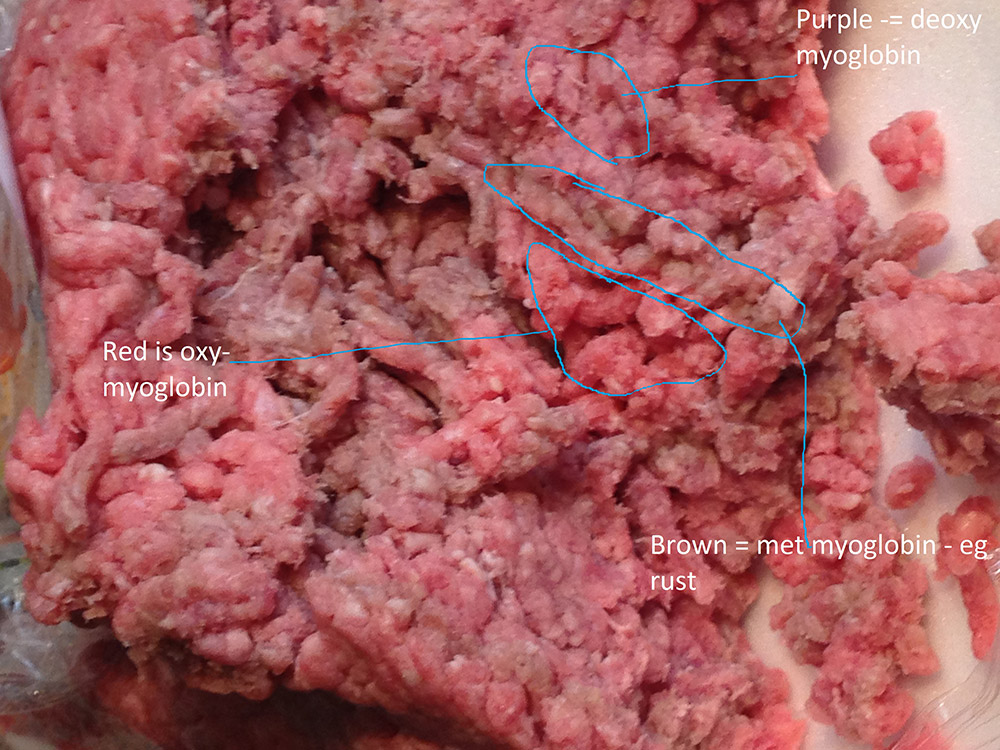

I have had people ask me in the past why supermarket ground beef is red on the outside and brown in the middle. Surprisingly, due to the nature of the pigment in ground beef, that is actually an indication of fresh ground beef – as long as it is bright pink on the outside and about half an inch into the package you see brown spots or brown through the center but pink on the outside. You only need to worry about ground beef if it is brown on the outside. That is an indication that it has been out too long. Ground beef has 3 normal color states – bright red (oxymyoglobin state), dark red-purple – deoxymyoglobin (no oxygen) and a state called met-myoglobin that is brown.

The meat starts out in a state oxymyoglobin (bright red) just after it is ground. When it goes into a package the inside portion isn’t getting oxygen any more, so it turns brown (met-myoglobin) before turning purple red (deoxymyoglobin). It takes about 2-4 hours for the ground beef to turn dark red after it is in the package. It has to go through the brown color before turning to the purple color – if you spread the package out and leave it in air it will re-bloom to bright red in 15 to 20 minutes. If you look carefully the first 1/4 to 1/2 inch; the meat will still be red. Sometimes it is splotchy brown because oxygen is getting to parts of the package but not all the way through. If the meat is old it gets brown on the surface first when it runs out of met-myoglobin reducing capacity. The meat at the surface runs out first and gets stuck in the brown state once the enzyme system runs out of energy.

Basically if the meat is brown on the inside when you open it up, and pink on the outside, the brown meat will turn pink in a short period of time showing that the meat is fresh.